- 20+ Years Of History

- 30+ Countries

- 50000 Yearly Production

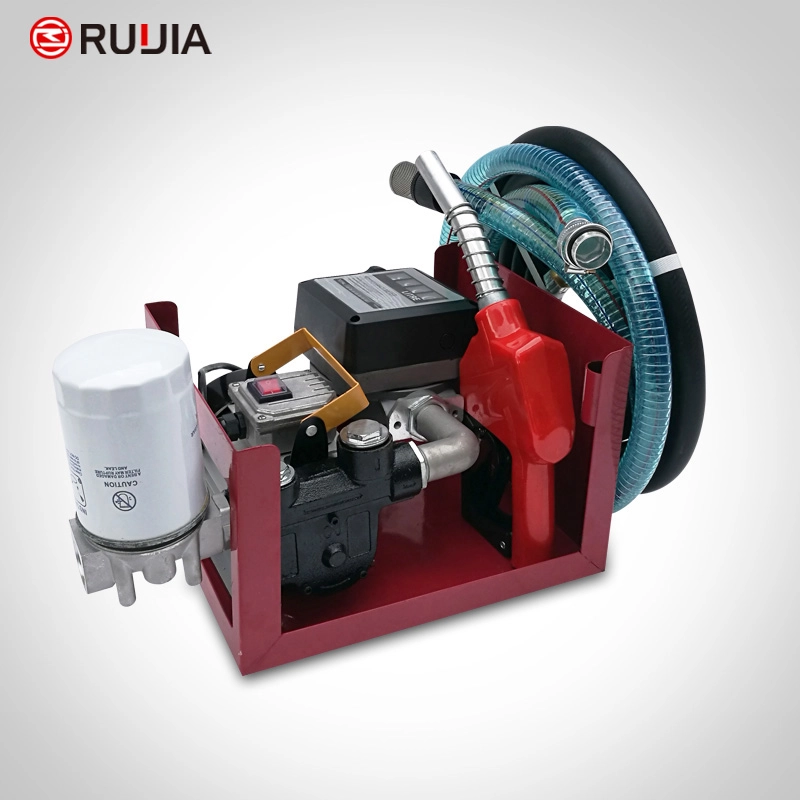

What is a Portable Diesel Transfer Pump

What is a Portable Diesel Transfer Pump?

A Comprehensive Guide

A portable diesel transfer pump is a versatile and essential tool designed to move diesel fuel between containers, storage tanks, or vehicles. Unlike fixed fuel dispensing systems, these fuel pumps are compact, lightweight, and easy to transport, making them ideal for a wide range of applications. Whether used in agriculture, construction, emergency response, or remote operations, portable diesel transfer pumps play a critical role in ensuring fuel accessibility and efficiency. This article explores the definition, functionality, key features, applications, and significance of portable diesel transfer pumps, shedding light on their importance in modern fuel management.

Definition and Core Functionality

A portable diesel transfer pump is a mechanical or electric device that transfers diesel fuel from one storage container to another, such as a vehicle’s fuel tank, a secondary tank, or a portable fuel can. These pumps are engineered to handle the specific properties of diesel fuel, including its viscosity, flammability, and resistance to evaporation. Their portability allows users to operate them in remote locations, where fixed fuel infrastructure may be unavailable.

The primary function of a portable diesel transfer pump is to provide a controlled and efficient method of moving fuel without the need for large, stationary equipment. This makes them particularly useful in scenarios where fuel must be transported over short distances or stored in multiple locations. Unlike traditional fuel dispensers, which are typically installed at gas stations or industrial sites, portable pumps are designed for flexibility and ease of use.

Key Components and Design Features

Portable diesel transfer pumps consist of several essential components that work together to ensure safe and efficient fuel transfer:

Pump Mechanism: The core of the device, which can be manual, electric, or pneumatic. Electric models are common for their speed and convenience, while manual pumps are preferred in areas without access to electricity.

Hose and Nozzle: A durable hose connects the pump to the source and destination containers. The nozzle is designed to fit standard fuel tank openings and often includes a locking mechanism to prevent accidental disconnection.

Valves and Pressure Regulators: These components control the flow of fuel, ensuring precise dispensing and preventing overfilling or spills. Some models feature automatic shut-off mechanisms that stop the pump when the tank is full.

Safety Features: To mitigate risks associated with diesel’s flammability, many portable pumps include spark-proof materials, grounding connections, and anti-static measures.

Power Source: Electric models are powered by batteries or external power supplies, while manual pumps rely on hand-operated mechanisms. Pneumatic pumps use compressed air, making them suitable for industrial settings.

The design of these pumps prioritizes durability, with materials like stainless steel, aluminum, and high-density polyethylene used to withstand harsh environments. Many models are also equipped with rugged casings to protect internal components from damage during transport.

How Portable Diesel Transfer Pumps Work

The operation of a portable diesel transfer pump depends on its type:

Manual Pumps: These require physical effort to operate, typically involving a lever or handle that creates suction to draw fuel from the source container. They are ideal for small-scale tasks but may be labor-intensive for large volumes.

Electric Pumps: Powered by electricity, these pumps use a motor to generate pressure and move fuel quickly. They are often used in commercial or industrial settings where speed and efficiency are critical.

Pneumatic Pumps: These use compressed air to create the necessary pressure for fuel transfer. They are commonly used in environments where electrical hazards are a concern, such as near flammable materials.

Regardless of the type, the process involves connecting the pump to the source and destination containers, activating the pump, and monitoring the flow until the desired amount of fuel is transferred. Safety protocols, such as grounding the pump to prevent static discharge, are essential to minimize risks.

Applications Across Industries

Portable diesel transfer pumps are widely used in diverse sectors due to their flexibility and reliability:

Agriculture: Farmers use these pumps to refill tractors, harvesters, and irrigation systems, especially in remote areas without access to fuel stations.

Construction: Heavy machinery like excavators, bulldozers, and generators rely on portable pumps to refuel on-site, reducing downtime and improving productivity.

Emergency Response: During natural disasters or power outages, portable pumps are critical for supplying fuel to emergency vehicles, generators, and temporary shelters.

Fleet Management: Companies with fleets of vehicles, such as delivery trucks or taxis, use portable pumps to refuel in areas where traditional gas stations are unavailable.

Marine and Aviation: Boats and small aircraft often depend on portable pumps for fueling, particularly in coastal or island communities.

Remote Operations: Industries operating in isolated locations, such as mining or oil exploration, use these pumps to transport fuel to remote sites.

Advantages of Portable Diesel Transfer Pumps

The popularity of portable diesel transfer pumps stems from their numerous benefits:

Portability: Their compact design allows them to be easily transported and used in various locations.

Cost-Effectiveness: Compared to fixed fuel infrastructure, portable pumps offer a lower initial investment and reduce the need for expensive storage facilities.

Versatility: They can be used for a wide range of tasks, from refueling vehicles to transferring fuel between tanks.

Safety: Modern designs incorporate features like anti-static protection and spill prevention, reducing the risk of accidents.

Convenience: Users can operate these pumps independently, eliminating the need for specialized personnel or equipment.

Challenges and Considerations

Despite their advantages, portable diesel transfer pumps face certain challenges:

Maintenance: Regular cleaning and inspection are required to prevent clogging from sediment or water in the fuel.

Environmental Impact: Improper disposal of used fuel or leaks can harm the environment, necessitating strict adherence to safety protocols.

Regulatory Compliance: Users must follow local regulations regarding fuel storage, transportation, and handling to avoid legal issues.

Limitations in Capacity: While suitable for small to medium volumes, these pumps may not be efficient for large-scale fuel transfers.

Future Trends and Innovations

As technology advances, portable diesel transfer pumps are becoming smarter and more sustainable. Innovations include:

Smart Pumps: Equipped with IoT (Internet of Things) sensors to monitor fuel levels, detect leaks, and optimize usage.

Eco-Friendly Designs: Pumps with energy-efficient motors and biodegradable materials are gaining traction.

Hybrid Systems: Combining diesel pumps with renewable energy sources, such as solar power, to reduce reliance on fossil fuels.

Conclusion

A portable diesel transfer pump is a vital tool that bridges the gap between fuel storage and consumption in diverse settings. Its portability, efficiency, and adaptability make it indispensable for industries ranging from agriculture to emergency response. As fuel demands continue to grow, the development of advanced, sustainable, and user-friendly portable pumps will play a crucial role in meeting global energy needs. By addressing challenges and embracing innovation, these pumps will remain a cornerstone of modern fuel management, ensuring reliable access to diesel in even the most remote and demanding environments.

1. Definition and Core Functionality

A portable diesel transfer pump is a self-contained pumping system that enables:

Fuel mobility: Transfer diesel without fixed pipelines (flow rates: 10–100 GPM).

Precision control: Accurate metering with ±1% volume variance.

Adaptability: Operates in remote/off-grid locations (common in mining/oilfields).

2. Key Components

2.1 Pump Mechanism

Rotary Gear Pumps: Most common type; handles viscous diesel efficiently.

Centrifugal Pumps: For high-flow applications (e.g., fleet refueling).

Diaphragm Pumps: Explosion-proof variants for hazardous areas.

2.2 Power Sources

Electric Motors: 12V/24V DC for vehicles; 110V/220V AC for industrial use.

Gasoline Engines: Field-deployable units (e.g., Honda GX series).

Solar Hybrids: Emerging in African/South Asian markets.

2.3 Filtration System

Two-stage filters: Remove particulates (10µm pre-filter + 2µm final filter).

Water separators: Critical for low-sulfur diesel (ULSD compatibility).

3. Operational Workflow

Suction Phase: Pump draws diesel via submerged intake hose.

Pressure Generation: Rotating gears/impellers create flow (15–60 PSI typical).

Filtration: Inline filters clean fuel before discharge.

Delivery: Nozzle-controlled output with auto-shutoff (API standards).

4. Industrial Applications

SectorUse CaseSpecial RequirementsAgricultureTractor refuelingDust-proof housingConstructionGenerator supplyHigh-flow (50+ GPM)MarineDock-to-ship transferCorrosion-resistant materialsEmergencyDisaster relief opsFAA-certified air transportability

5. Advantages Over Fixed Systems

Cost Efficiency: 60% lower installation cost vs. permanent dispensers.

Mobility: Weights as low as 15 kg (aluminum models).

Compliance: Meets EPA Tier 4 and EU Stage V emissions norms.

6. Maintenance Protocols

Daily: Inspect hoses/seals for leaks.

Monthly: Clean filters; test emergency shutoffs.

Annual: Replace wear parts (seals, gaskets).

7. Emerging Innovations

IoT Integration: Real-time fuel tracking via GSM modules.

Battery-Powered: Cordless pumps (e.g., DeWalt 20V MAX system).

AI Diagnostics: Predictive maintenance alerts for impeller wear.

8. Safety Features

Grounding wires: Prevent static ignition (OSHA 1910.106 compliant).

Dry-run protection: Automatic shutdown when fuel is depleted.

Explosion-proof ratings: ATEX Zone 1 certification for oil rigs.

9. Market Trends (2025 Outlook)

Asia-Pacific dominance: 42% market share led by Indian/Chinese OEMs.

Biofuel adaptation: Pumps modified for B20 biodiesel blends.

Rental models: Growing popularity in EU contractor markets.

The Mobile Powerhouse: Unveiling the Portable Diesel Transfer Pump

In countless settings where stationary fuel infrastructure is impractical, unavailable, or overwhelmed, a critical tool takes center stage: the portable diesel transfer pump. This self-contained, compact, and versatile unit is engineered for one fundamental purpose: to efficiently and reliably move diesel fuel from one container, tank, or source to another, directly at the point of need. It serves as a vital piece of equipment bridging gaps in fixed systems and enabling fuel logistics in dynamic, temporary, or remote environments.

Beyond a Simple Pump: Core Purpose and Defining Features

While the core action is pumping fluid, a portable diesel transfer pump is distinct in its design and application:

Mobility: The defining characteristic. Designed with handles, wheels, or a compact frame for easy manual transport by individuals, typically without requiring lifting equipment.

Self-Containment: Integrates the pump unit, drive mechanism (motor/engine), necessary hoses, and often filtering elements into a single, ready-to-operate package.

Versatility: Capable of transferring diesel from diverse sources (drums, totes, storage tanks, vehicle tanks, bowers) to diverse receivers (machinery tanks, generators, vehicles, secondary storage tanks, day tanks).

On-Demand Operation: Operates independently of fixed power sources (when equipped with an engine or DC power) at the precise location where fuel needs moving.

Simplicity: Designed for relatively quick setup and operation by personnel without extensive specialized training.

Anatomy of a Workhorse: Key Components

A typical portable diesel transfer pump comprises several essential parts:

Pump Head: The hydraulic heart. Common types include:

Rotary Vane Pumps: Known for self-priming capability, smooth flow, quiet operation, and good suction lift. Common for lower to medium flow rates. Wear vanes may need periodic replacement.

Gear Pumps (Internal or External): Rugged, simple, handle a wide range of viscosities effectively. Good for medium flow rates and pressures. Generally less self-priming than vanes.

Centrifugal Pumps: Best for high flow rates at lower pressures where suction lift is minimal (e.g., transferring from a tanker to a storage tank near ground level). Often require priming.

Diaphragm Pumps: Often used for smaller volumes or metering applications. Handle entrained air well and can run dry without damage. Can be noisy.

Drive Mechanism:

Electric Motor: Requires a power source (AC mains 110V/230V or DC 12V/24V from batteries). AC motor pumps offer consistent power; DC models offer ultimate portability using vehicle batteries or standalone battery packs. Must be rated for hazardous locations (explosion-proof or intrinsically safe) due to flammable diesel vapors.

Gasoline/Petrol Engine: Provides true independence from electrical grids. Essential for remote sites or where mains power is unavailable. Requires fueling and maintenance like any small engine.

PTO (Power Take-Off): Some heavy-duty models connect directly to a tractor or truck PTO for high-power operation.

Frame/Enclosure: Provides structural support, mounting points for components, and handles/wheels for transport. Often made of painted or galvanized steel. May include fuel tank and controls.

Hoses & Couplings:

Suction Hose: Typically reinforced, often with a strainer/foot valve at the source end. Must resist collapsing under vacuum. Length affects suction lift.

Discharge Hose: Handles the pressurized flow to the receiver. Varies in length and pressure rating.

Quick-Connect Couplings: Enable fast, spill-free connection/disconnection of hoses to the pump and various nozzles/bungs.

Filter(s): Critical for protecting downstream equipment (like sensitive injector systems).

Pre-Filter (Strainer): Coarse screen at the suction inlet to catch large debris.

Main Filter: Fine particulate filter (common ratings: 10 micron, 5 micron, or even 2 micron) located either on the suction or discharge side. Water-blocking filters are increasingly standard.

Nozzle/Pistol Grip: Controls the flow at the discharge end. Trigger-operated pistol grips are common for filling tanks. Automatic shut-off nozzles prevent overfilling. Open-ended nozzles work for drums or open tanks.

Priming Mechanism: Varies by pump type. Vane and gear pumps often self-prime up to a certain height (e.g., 10-25 feet). Centrifugal pumps may need manual priming (filling the casing/hose with fuel).

Control/Protection: May include an on/off switch, motor thermal overload protection, and sometimes flow rate control valves.

Why Portability Matters: Core Applications

The unique advantages of portable transfer pumps make them indispensable in numerous scenarios:

Construction Sites: Fueling excavators, dozers, graders, generators, light towers, and other diesel-powered equipment directly from on-site fuel storage (drums, mini-tanks). Eliminates costly downtime moving equipment to a fixed pump.

Agriculture: Refueling tractors, combines, irrigation pumps, and other farm machinery in fields far from the main farm fuel depot.

Mining & Quarrying: Similar needs to construction, often in extremely remote locations with harsh conditions.

Marine: Transferring fuel from shore storage to boats or between vessels. Fueling generators or auxiliary equipment on board.

Emergency Services & Disaster Relief: Powering generators, vehicles, and equipment rapidly in areas where infrastructure is damaged or non-existent (hurricanes, earthquakes, floods).

Transport & Logistics: Topping up truck tanks from bowers; draining contaminated fuel; defueling vehicles for maintenance or disposal; transferring fuel from transport containers (drums/totes) into larger storage tanks.

Generator Fueling: Ensuring continuous power for backup generators at data centers, hospitals, cell towers, and facilities by refilling day tanks or directly from bulk storage.

Remote Facilities: Any site lacking permanent fueling infrastructure: research stations, telecommunication towers, pipeline stations.

Industrial Maintenance: Transferring fuel for tank cleaning, maintenance, or recirculation/filtration operations.

Key Selection Criteria: Matching Pump to Purpose

Choosing the right pump requires careful consideration of specific needs:

Flow Rate Requirement: How many liters/gallons per minute (LPM/GPM) are needed? Affects transfer time significantly (e.g., filling a large excavator vs. a small generator).

Suction Lift Required: Vertical distance the pump must lift fuel from the source to the pump inlet. Critical for drums or tanks below ground level. Pumps specify max lift capability (e.g., 6m / 20ft).

Discharge Pressure: How much pressure is needed to overcome friction in hoses/pipes and push fuel into the receiver? Higher pressure needed for longer hoses, smaller diameter hoses, or specific nozzles.

Power Source: Grid power (AC)? Vehicle battery (DC)? Need independence (Gas engine)? Dictates drive mechanism choice. DC/Gas is essential for true portability away from mains.

Flow Meter: Is accurate measurement of transferred volume crucial? Some pumps have integrated mechanical or electronic flow meters.

Filtration Level: How critical is fuel cleanliness? Choose filter micron rating based on the sensitivity of downstream engines/equipment. Water blocking essential in humid climates or with potential water ingress.

Hose Length & Size: Needed for source access? Affects suction performance and discharge pressure/flow.

Nozzle Type: Standard open nozzle, pistol grip (manual shut-off), or automatic shut-off?

Durability & Environment: Required for harsh, dirty, or wet conditions? Look for robust construction (steel frame), sealed motors (IP rating), and ingress protection.

Safety Certifications: Essential for electrical components: ATEX, IECEx, UL HazLoc certification for Zone 1 or Zone 2 hazardous (flammable vapor) locations. Gas engine models must be intrinsically safe or have proper spark arrestors/vents.

Diesel Compatibility: Ensure seals and wetted parts are resistant to diesel and biodiesel blends.

Advantages of Portable Diesel Transfer Pumps:

Increased Operational Efficiency: Save time and labor costs by eliminating machine movement.

Enhanced Flexibility: Adapt to changing site layouts or fuel storage locations.

Improved Safety: Reduce risks associated with moving heavy equipment solely for refueling (especially on slopes or unstable ground).

Reduced Spillage: Controlled pumping vs. manual pouring from drums or jugs.

Better Fuel Management: Integrated filtration improves fuel quality, protecting expensive engines.

Cost-Effectiveness: Avoids the high capital expense of installing fixed fueling infrastructure at temporary sites.

Safety Imperatives: Handling Flammable Liquids

Operating a portable diesel pump carries inherent risks:

Fire & Explosion Hazard: Diesel vapors and mists are flammable. Use only pumps with appropriate safety certifications for hazardous locations.

Static Electricity: Always ground both the pump frame and both the source and receiver containers before and during transfer using dedicated grounding cables and clamps. Critical!

Ventilation: Operate in well-ventilated areas to prevent vapor accumulation.

Spill Prevention: Use properly sized containment (drip trays, bunds) and spill kits. Don't leave pumps unattended.

Electrical Safety: Inspect cords/cables; use GFCI protection near AC mains; never use damaged equipment.

Personal Protective Equipment (PPE): Wear safety glasses, gloves, and sturdy footwear.

Conclusion: The Indispensable Fluid Mover

The portable diesel transfer pump is an unsung hero enabling productivity across a vast spectrum of industries. More than just a pump, it's a self-sufficient fuel logistics solution. By offering mobility, adaptability, and efficiency, it solves a fundamental problem: moving diesel safely and reliably from where it's stored to where it's needed, precisely when and where it's required. From powering recovery efforts after disaster to keeping vital construction projects on schedule or ensuring farm machinery operates seamlessly in distant fields, the portable diesel transfer pump embodies practical engineering at its most effective. Understanding its components, capabilities, and critical safety requirements ensures this powerful tool continues to fuel progress wherever wheels turn, engines roar, or generators hum.