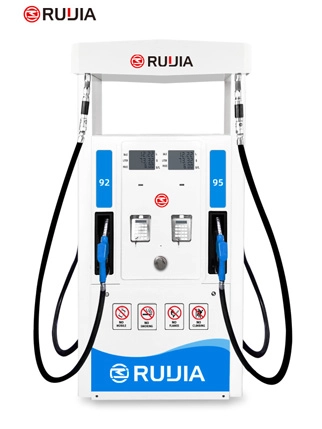

Gas Station Fuel Dispenser

Product Parameter

- Product Name

- RJ135 Fuel Dispenser

- Brand Name

- Ruijia

- Product Size

- 700X430X1350mm

- Nozzle

- 1 Nozzles

- Flow Meter

- 4- piston Flow Meter

- Pump

- Vane Pump, Gear Pump

- Lcd Display

- 664, 886

- Temperature

- -25°C~ +55°C

- Pressure

- 0.3MPa

- Accuracy

- ±0.3%

- IC Card

- Supports

- Flow Rate

- 5~60L/min or 5~100L/min

- Voltage

- AC 110V/220V/380V(50/60Hz)

- Suction Distance

- 6m(vertical), 50m(horizontal)

- Power

- 750W or 1100W

- Medium

- Gasoline, Diesel, Kerosene

Product Configuration

Our Certification

What is Gas Station Fuel Dispenser?

Ever pulled into a bustling gas station, surrounded by the hum of engines and the chatter of fellow motorists, and found yourself gazing at those imposing, metallic contraptions with hoses dangling like serpents? Those aren't just random machines; they're the lifeblood of the station, the gas station fuel dispensers! But what exactly are these marvels of engineering that we interact with so frequently yet often understand so little about? Are they merely simple fuel - pumping devices, or do they hide a universe of intricate technology and innovation beneath their rugged exteriors? Brace yourself for an electrifying exploration into the world of gas station fuel dispensers that will leave you astounded at their complexity and ingenuity!

At first blush, a gas station fuel dispenser might appear as a monolithic, unremarkable box. But oh, how deceptive appearances can be! Beneath that unassuming facade lies a symphony of advanced technology, a meticulously crafted ecosystem where every component plays a crucial role in the grand performance of fueling our vehicles. It's like a hidden city, with a network of roads and buildings (or in this case, wires and pipes) all working in harmony to ensure a seamless refueling experience. These dispensers aren't just the result of haphazard design; they're the fruit of years of research, development, and a relentless pursuit of perfection in the ever - evolving fueling industry.

The primary mission of a gas station fuel dispenser is crystal clear: to measure, control, and deliver fuel from the vast underground storage tanks to our waiting vehicles. But don't be fooled by the simplicity of this task description. Executing it with precision is no mean feat, requiring a level of sophistication that rivals some of the most complex machinery in existence. Picture the dispenser as a skilled tightrope walker, deftly balancing multiple variables – pressure, flow rate, volume – all at once to ensure that each drop of fuel reaches its destination accurately and safely. It's a high - stakes act, where even the slightest miscalculation could lead to issues ranging from inaccurate billing to potential safety hazards.

Let's start our journey into the inner workings by examining the pumping mechanism, the very heart and soul of the gas station fuel dispenser. This isn't your run - of - the - mill pump; it's a high - octane powerhouse engineered to overcome the unique challenges posed by different types of fuels and the distances they must travel from the storage tanks to our vehicles. Specialized electric motors, often custom - built with intricate configurations, serve as the driving force behind these pumps. They rumble and hum with raw power, generating the pressure needed to push fuel through a labyrinthine network of hoses and pipes. Think of these motors as the mighty engines of a locomotive, chugging away to propel the precious cargo of fuel towards its final destination. The power and efficiency of these motors are not just numbers on a spec sheet; they directly impact how quickly and smoothly we can refuel our cars, especially during peak hours when lines at the gas station stretch as far as the eye can see.

Attached to the pumping mechanism are the hoses, the vital lifelines that carry the fuel from the dispenser to our vehicle's tank. These aren't ordinary rubber tubes; they're high - tech conduits crafted from a blend of super - strong, fuel - resistant materials. Engineered to endure the daily grind of use, the corrosive nature of fuels, and the mechanical stress of constant maneuvering, they're like the indestructible arteries of the fueling system. Some hoses even feature cutting - edge reinforcement layers, acting as a suit of armor to shield against abrasion and potential leaks. And at the end of these hoses, the nozzles await – the gatekeepers of the fueling process. Precision - engineered with automatic shut - off valves, these nozzles are like vigilant sentinels standing guard. The instant a vehicle's tank reaches capacity, these valves spring into action, halting the fuel flow with lightning speed and preventing messy overflows. It's a split - second operation that showcases the dispenser's remarkable ability to balance speed and safety, ensuring that our refueling experience is both efficient and worry - free.

But the functionality of a gas station fuel dispenser extends far beyond mere pumping and dispensing. Accuracy is the name of the game, and that's where the metering system steps into the spotlight. Two main types of metering technologies dominate the landscape: positive displacement meters and turbine flow meters. Positive displacement meters operate on a fascinating principle of trapping and transferring fixed volumes of fuel. Inside these mechanical wonders, components like pistons or gears move in a perfectly choreographed dance, counting each unit of fuel as it passes through. It's as if there's a tiny factory inside the meter, with each part playing its role to ensure that the volume of fuel dispensed is measured with jaw - dropping precision. Turbine flow meters, on the other hand, are a testament to the elegance of fluid dynamics. As fuel rushes through, it sets a turbine spinning, and sensors detect the rotational speed. Through a series of complex calculations, this speed is translated into an accurate measurement of the fuel volume. It's like using the rotation of a windmill to gauge the strength of the wind, but in the context of fuel flow – a brilliant application of physics in the world of fueling.

The control panel of a gas station fuel dispenser is the bridge between the machine and the user, the portal to a seamless refueling experience. Modern control panels are a far cry from the clunky, mechanical dials of yesteryears. They're sleek, intuitive touch - screen interfaces that light up like a futuristic dashboard. Here, customers are in the driver's seat, able to select the type of fuel they need – whether it's regular unleaded, premium high - octane, diesel, or even alternative fuels in some forward - thinking stations. Payment authorization is a breeze, with a plethora of options at our fingertips, from swiping traditional credit cards to tapping our smartphones for contactless payments. Some control panels even offer a wealth of real - time information, displaying the price per gallon, the volume of fuel already dispensed, and the running total cost. It's like having a personal concierge at the gas station, guiding us through the process and keeping us informed every step of the way.

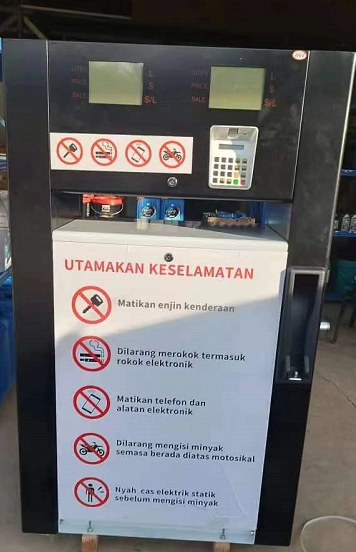

Safety, of course, is non - negotiable when it comes to gas station fuel dispensers. Given that fuel is a highly combustible substance, even the smallest oversight could trigger a catastrophic chain of events. To ward off such risks, these dispensers are armed to the teeth with an array of safety features. Grounding systems are installed as a safeguard against static electricity, which could potentially ignite fuel vapors. These systems act like a lightning rod, safely directing any electrical charge away and preventing sparks from flying. Overfill prevention devices, in addition to the automatic shut - off valves in the nozzles, add an extra layer of protection. Using state - of - the - art sensors, they can detect when a tank is nearing its capacity and trigger an emergency shut - off of the entire dispenser if needed. And in case of any unforeseen emergencies, prominently marked emergency stop buttons are strategically placed, allowing anyone to halt the fueling process in the blink of an eye. It's a comprehensive safety net that leaves no room for error.

Maintenance of gas station fuel dispensers is the key to their longevity and reliable operation. Regular inspections are a must, with technicians playing the role of meticulous detectives, carefully examining every nook and cranny of the dispenser. Hoses are scrutinized for signs of wear and tear, such as cracks or leaks, and replaced at the first sign of trouble. Nozzles are cleaned thoroughly to remove any debris or sediment that could disrupt fuel flow or compromise the accuracy of the metering system. The metering system itself undergoes periodic calibration, a delicate process that ensures it continues to provide precise measurements. And the electrical components, including the pumps and control panels, are put through their paces to prevent any malfunctions. It's a painstaking process, much like a master mechanic tuning up a high - performance race car, ensuring that the gas station fuel dispenser remains in peak condition, ready to serve countless motorists day in and day out.

The evolution of gas station fuel dispensers is a captivating tale of innovation. From the early days of manual pumps, where customers had to physically work a lever to draw fuel, to the highly automated, computer - controlled behemoths of today, the transformation has been revolutionary. The introduction of electronic metering systems was a game - changer, replacing old - fashioned mechanical counters with digital sensors and microprocessors. This leap forward enabled far more precise and reliable fuel measurement, changing the way we think about refueling. And with the advent of new technologies like the Internet of Things (IoT), gas station fuel dispensers are becoming smarter and more connected than ever before. They can now communicate with central systems, allowing operators to monitor their performance in real - time, detect potential issues before they escalate, and even perform remote diagnostics and maintenance. It's a brave new world for these essential pieces of equipment.

Looking to the horizon, the future of gas station fuel dispensers is filled with boundless possibilities. As the world marches towards a more sustainable future, these dispensers will need to adapt to new types of fuels. The rise of electric vehicles has already started to reshape the fueling landscape, with some gas stations integrating charging capabilities alongside traditional fuel dispensers. In the not - too - distant future, gas station fuel dispensers may be equipped to handle alternative fuels such as hydrogen or biofuels, opening up a whole new chapter in the story of transportation. Additionally, the integration of artificial intelligence and machine learning could take the functionality of these dispensers to unprecedented heights. Imagine a dispenser that can predict your vehicle's fuel needs based on your driving habits, or one that offers personalized recommendations on the most cost - effective fuel options. It's a future where gas station fuel dispensers are no longer just machines; they're intelligent companions on our journey, seamlessly blending into our lives and making refueling a more convenient and personalized experience.

In conclusion, the gas station fuel dispenser is a true icon of modern engineering. It's a complex, high - tech marvel that combines power, precision, safety, and innovation in a single, remarkable package. From its pumping mechanism and metering system to its control panel and safety features, every aspect is a testament to human ingenuity and the relentless pursuit of excellence. As we look ahead, there's no doubt that these dispensers will continue to evolve, adapting to new technologies and changing consumer demands. So, the next time you pull up to a gas station and approach one of these incredible machines, take a moment to appreciate the engineering masterpiece that stands before you. It's not just a device for pumping fuel; it's a symbol of our progress, a vital part of our daily lives, and a key player in the ever - evolving story of transportation.