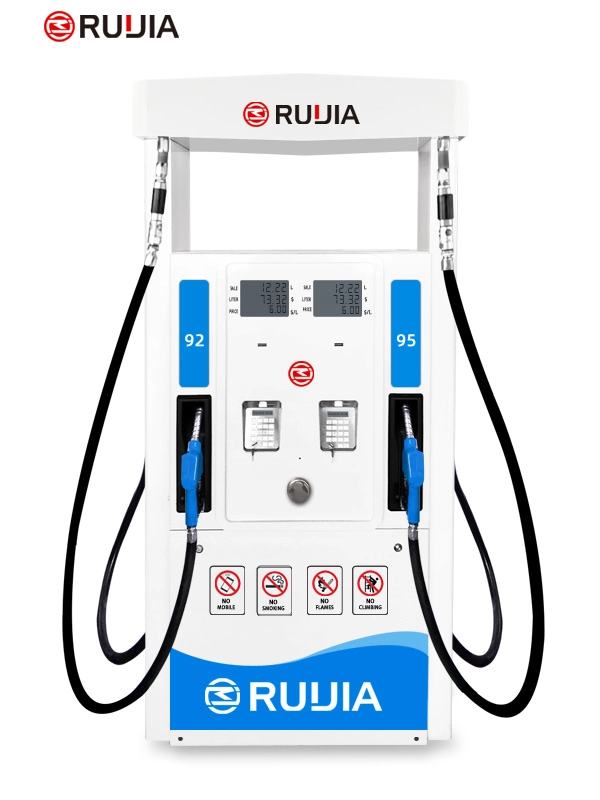

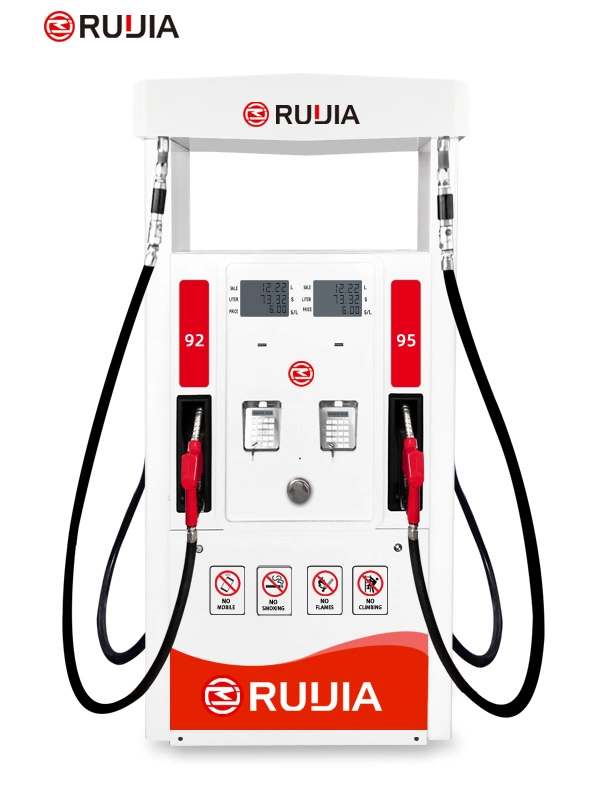

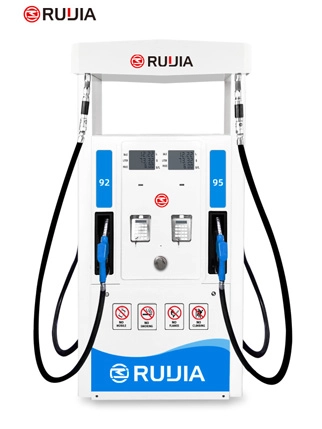

Four Nozzles Fuel Dispenser

Product Parameter

- Product Name

- RJ2304 Fuel Dispenser

- Brand Name

- Ruijia

- Product Size

- 1100X620X2250 mm

- Nozzle

- 4 Nozzles

- Flow Meter

- 4- piston Flow Meter

- Pump

- Vane Pump, Gear Pump

- Lcd Display

- 664, 886

- Temperature

- -25°C~ +55°C

- Pressure

- 0.3MPa

- Accuracy

- ±0.3%

- IC Card

- Supports

- Flow Rate

- 5~60L/min or 5~100L/min

- Voltage

- AC 110V/220V/380V(50/60Hz)

- Suction Distance

- 6m(vertical), 50m(horizontal)

- Power

- 750W or 1100W

- Medium

- Gasoline, Diesel, Kerosene

Product Configuration

Our Certification

About this item

Ever watched a busy beehive? The constant flurry, the synchronized chaos, and every member playing their part with precision. Now, picture that organized frenzy in the world of fuel distribution, and you've got the Four Nozzles Fuel Dispenser—a mechanical marvel that turns the fueling process from a drawn - out chore into a finely tuned ballet. In a domain where every second counts and efficiency is king, this device has emerged not just as a tool, but as a disruptor, redefining the very fabric of how we power the world.

The first time you lay eyes on a Four Nozzles Fuel Dispenser, it might seem like an imposing monolith. Towering over the fueling station, its robust frame, often clad in weather - resistant steel or composite armor, stands as a testament to its durability. But don't be fooled by its sturdy exterior; inside lies a symphony of components working in harmony, a mechanical orchestra if you will.

So, what exactly makes this four - nozzle titan tick? At its essence, it's a revolutionary fueling apparatus designed to shatter the limitations of traditional single - nozzle counterparts. While a single - nozzle dispenser plods along, attending to one vehicle at a time like a lone worker in a vast factory, the Four Nozzles Fuel Dispenser operates on a whole different plane. It's engineered to handle the simultaneous or sequential dispensing of fuel through four distinct nozzles, each a gateway to a world of enhanced productivity and flexibility.

Let's take a peek under the hood, so to speak. The casing of the Four Nozzles Fuel Dispenser isn't just for show; it's a fortress protecting a network of intricate pipes, valves, and sensors. These pipes, snaking their way through the interior like veins in a mechanical body, carry the lifeblood of the operation—fuel. The valves, on the other hand, act as gatekeepers, controlling the flow with a level of precision that would make a surgeon envious. And then there are the sensors, the vigilant sentinels constantly monitoring every aspect of the fueling process, from detecting the slightest leak to gauging fuel levels with unerring accuracy.

But the true magic of the Four Nozzles Fuel Dispenser doesn't stop at its hardware. It's the software and control systems that elevate it from a mere machine to a technological powerhouse. Imagine a cockpit filled with advanced digital displays that light up like a futuristic control panel. These displays offer real - time insights into fuel flow rates, volume dispensed, and pricing, putting the power of knowledge in the hands of both operators and customers. The smart sensors, in collaboration with the software, can even adapt the flow rate based on the unique characteristics of the vehicle or container being fueled. It's as if the dispenser has a mind of its own, intuitively adjusting to meet the demands of each fueling task.

The efficiency of the Four Nozzles Fuel Dispenser is nothing short of astonishing. Consider a mammoth truck stop teeming with colossal semi - trucks, their engines rumbling impatiently as they wait to be refueled. In a traditional setup, this could mean hours of delay, a bottleneck that grinds the gears of commerce to a halt. But with a Four Nozzles Fuel Dispenser on the scene, it's a different story. Like a skilled juggler tossing multiple balls in the air, it can simultaneously fuel four trucks, slashing wait times and boosting throughput exponentially. The result? A steady stream of trucks back on the road, keeping the supply chains moving and the economy humming.

And the flexibility! Oh, the flexibility of this remarkable device! Each of the four nozzles is a chameleon, capable of dispensing a wide variety of fuels. From the high - octane gasoline that powers sports cars to the diesel that roars in the engines of heavy - duty trucks, and even the specialized aviation fuel that propels planes into the skies, the Four Nozzles Fuel Dispenser can handle it all. This makes it an absolute godsend for mixed - fleet operations. Take a large delivery company, for example. They might have a fleet that includes sleek gasoline - powered vans for local deliveries, rugged diesel trucks for long - haul journeys, and even some eco - friendly electric vehicles in the mix. With a Four Nozzles Fuel Dispenser, they can fuel their entire fleet from a single station, streamlining operations and reducing the headache of managing multiple fueling systems.

The industrial sector has also embraced the Four Nozzles Fuel Dispenser with open arms. On a sprawling construction site, where a legion of excavators, bulldozers, and loaders work around the clock, downtime is the enemy. A single breakdown due to lack of fuel can cascade into a series of delays, pushing back project timelines and inflating costs. But with a Four Nozzles Fuel Dispenser on - site, fueling becomes a seamless process. It can quickly top up multiple machines, ensuring that the construction project continues at full steam ahead. It's like having a pit crew for heavy machinery, keeping everything in peak condition and ready to roll.

Of course, no technological marvel comes without its challenges. Installing a Four Nozzles Fuel Dispenser is no walk in the park. It requires a team of highly skilled technicians, well - versed in the intricacies of fueling systems, to ensure proper setup. Maintenance is another crucial aspect. Regular inspections, calibration, and servicing are non - negotiable to keep the dispenser running smoothly. And let's not forget the initial investment. These machines don't come cheap, and businesses need to carefully weigh the costs against the long - term benefits. But make no mistake, for those who can afford it, the return on investment is substantial.

As the world marches towards a more sustainable future, the Four Nozzles Fuel Dispenser is also evolving. Manufacturers are racing to develop models that are compatible with alternative fuels. Hydrogen - powered vehicles are no longer a distant dream, and electric vehicle charging infrastructure is expanding rapidly. The Four Nozzles Fuel Dispenser is poised to adapt, with some models already featuring ports for electric vehicle charging alongside traditional fuel nozzles. It's a sign of the times, a testament to the device's ability to stay relevant in an ever - changing technological landscape.

In the grand tapestry of fuel distribution, the Four Nozzles Fuel Dispenser is a vibrant thread, weaving together efficiency, flexibility, and innovation. It's not just a piece of equipment; it's a catalyst for change, a symbol of human ingenuity's ability to overcome challenges and find better ways of doing things. Whether it's at a bustling truck stop, a busy airport, or a massive industrial complex, this four - nozzle wonder continues to prove its worth, one fueling session at a time. It's a reminder that in the world of technology, the only constant is change, and the Four Nozzles Fuel Dispenser is riding the wave of progress with style and substance.