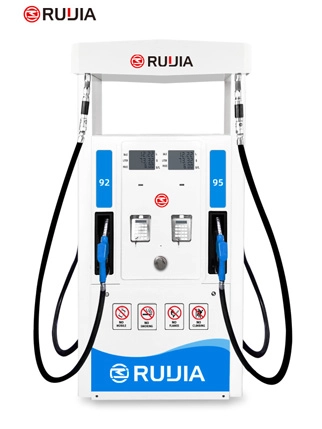

Diesel Fuel Dispenser

Product Parameter

- Product Name

- RJ2202 Fuel Dispenser

- Brand Name

- Ruijia

- Product Size

- 1120X470X1900mm

- Nozzle

- 2 Nozzles

- Flow Meter

- 4- piston Flow Meter

- Pump

- Vane Pump, Gear Pump

- Lcd Display

- 664, 886

- Temperature

- -25°C~ +55°C

- Pressure

- 0.3MPa

- Accuracy

- ±0.3%

- IC Card

- Supports

- Flow Rate

- 5~60L/min or 5~100L/min

- Voltage

- AC 110V/220V/380V(50/60Hz)

- Suction Distance

- 6m(vertical), 50m(horizontal)

- Power

- 750W or 1100W

- Medium

- Gasoline, Diesel, Kerosene

Product Configuration

Our Certification

What is a Diesel Fuel Dispenser?

Ever pulled into a fuel station, eyes drawn to that robust, often towering machine labeled "Diesel," and wondered what makes it tick? Behold the diesel fuel dispenser, a titan in the realm of fueling infrastructure, a mechanical maestro that orchestrates the transfer of diesel fuel with precision and power. It's not merely a conduit for fuel; it's a crucial cog in the vast machinery of modern transportation, silently fueling the trucks that carry our goods, the buses that shuttle commuters, and the heavy - duty equipment that shapes our world. But what exactly sets this dispenser apart from its gasoline - dispensing counterparts? Let's plunge into the depths of its design, functionality, and significance.

At first glance, a diesel fuel dispenser might seem like just another fuel - dispensing device. Yet, beneath its exterior lies a world of specialized engineering tailored to the unique properties of diesel fuel. Diesel, denser and more viscous than gasoline, demands a dispenser built to handle its characteristics. Picture it as a rugged workhorse, designed to endure the rigors of dispensing a fuel that powers some of the most robust engines on the planet.

The heart of a diesel fuel dispenser is its pumping mechanism, a powerhouse engineered to overcome the inherent challenges posed by diesel's viscosity. Unlike gasoline, which flows more freely, diesel requires a more forceful push to travel through the hoses and into the vehicle's tank. High - pressure pumps, often driven by robust electric motors, are the norm. These pumps work tirelessly, generating the pressure needed to propel diesel fuel at a steady rate, much like a determined river guide navigating a vessel through a turbulent stream. The motors are designed with durability in mind, capable of withstanding continuous operation and the demands of high - volume fueling.

Connected to the pumping mechanism are the hoses, the lifelines of the diesel fuel dispenser. Crafted from heavy - duty materials, these hoses are a far cry from their gasoline - dispensing counterparts. They're thicker, more resilient, and built to handle the higher pressures and temperatures associated with diesel fuel. Reinforced with layers of synthetic fibers or metal braiding, they resist abrasion, cracking, and fuel permeation. Imagine these hoses as armored pathways, safeguarding the precious diesel fuel as it makes its journey from the dispenser to the vehicle. The nozzles at the end of these hoses are equally specialized. Designed with larger diameters to accommodate the thicker diesel flow, they often feature ergonomic grips for ease of use, especially when fueling large trucks or equipment. And of course, they're equipped with automatic shut - off valves, those ever - vigilant guardians that halt the fuel flow the moment the tank reaches capacity, preventing messy overflows.

But the diesel fuel dispenser's functionality doesn't stop at simply pumping and dispensing fuel. Accuracy is paramount, and that's where the metering system comes into play. Similar to other fuel dispensers, diesel models rely on metering devices to measure the volume of fuel dispensed. Positive displacement meters are commonly used in diesel fuel dispensers. These meters work by trapping discrete volumes of diesel fuel within their chambers and then counting each "packet" as it passes through. It's a bit like a meticulous counter, tallying up every drop of diesel with unwavering precision. Some advanced dispensers even incorporate electronic metering systems, using sensors and microprocessors to provide highly accurate measurements. These systems can compensate for factors like temperature variations, which can affect the density of diesel fuel, ensuring that customers get exactly what they pay for.

Safety is a top - priority in the design of diesel fuel dispensers, and for good reason. Diesel fuel, while less volatile than gasoline, still poses risks. Static electricity, for instance, can build up during the fueling process and potentially ignite the fuel vapors. To combat this, diesel fuel dispensers are equipped with robust grounding systems. These systems create a pathway for static charges to dissipate harmlessly into the ground, acting as a shield against potential sparks. Overfill prevention devices are another crucial safety feature. In addition to the automatic shut - off valves in the nozzles, some dispensers have sensors that detect when the fuel level in the tank is approaching its maximum capacity. If necessary, these sensors can trigger an emergency shut - off of the dispenser, preventing fuel spills that could contaminate the environment or pose a fire hazard.

The control panel of a diesel fuel dispenser is the interface between the machine and the user. It's where customers select the type of fuel (in this case, diesel, of course), authorize payment, and monitor the fueling process. Modern control panels are sleek and intuitive, often featuring touch - screen displays. They provide real - time information such as the volume of fuel dispensed, the price per gallon or liter, and the total cost. Some even integrate with loyalty programs, allowing customers to earn points or discounts with each fill - up. It's like having a personal assistant at the fuel station, guiding you through the refueling experience with ease.

Maintenance of diesel fuel dispensers is a critical aspect of ensuring their reliable operation. Given the demanding nature of diesel fuel and the heavy - duty use these dispensers often endure, regular upkeep is non - negotiable. Technicians must regularly inspect the hoses for signs of wear and tear, checking for cracks, leaks, or abrasions. The nozzles need to be cleaned to remove any accumulated debris or sediment that could affect fuel flow or accuracy. The metering system requires periodic calibration to ensure its continued precision. And of course, the pumping mechanism and electric motors need to be serviced to prevent breakdowns. It's a comprehensive process, much like a thorough tune - up for a high - performance engine, ensuring that the diesel fuel dispenser remains in peak condition.

The role of diesel fuel dispensers in the economy cannot be overstated. They are the lifeblood of industries that rely on diesel - powered vehicles and equipment. From the trucking industry, which transports goods across the country, to construction sites where heavy machinery digs, lifts, and builds, diesel fuel dispensers keep these operations running. Without them, supply chains would grind to a halt, construction projects would stall, and the wheels of commerce would cease to turn. They're the unsung heroes that enable the movement of goods and services, facilitating economic growth and development.

As the world evolves, so too do diesel fuel dispensers. With the growing focus on environmental sustainability, there's a push towards cleaner diesel fuels and more efficient dispensing technologies. Ultra - low - sulfur diesel (ULSD) has become the standard in many regions, reducing emissions of harmful pollutants. Diesel fuel dispensers are being adapted to handle these new fuels, often with enhanced filtration systems to remove any remaining impurities. Additionally, there's research into alternative fuels derived from bio - sources or synthetic processes that could potentially be dispensed through modified diesel fuel dispensers. It's an exciting time of innovation, as these dispensers are set to play a role in a more sustainable future.

In the realm of smart technology, diesel fuel dispensers are also getting a digital makeover. Some are being equipped with Internet of Things (IoT) sensors that allow for remote monitoring. Fuel station operators can track the dispenser's performance in real - time, receive alerts if there are any issues, and even analyze data to optimize operations. Predictive maintenance, made possible by these sensors, can help prevent costly breakdowns by identifying potential problems before they occur. It's as if the diesel fuel dispenser is gaining a "mind" of its own, communicating with operators to ensure its smooth and efficient operation.

In conclusion, the diesel fuel dispenser is a remarkable piece of engineering, a vital component of our modern fueling infrastructure. From its powerful pumping mechanism and specialized hoses to its accurate metering system and robust safety features, every aspect is designed with purpose. It fuels the engines that drive our economy, and as technology advances, it's set to evolve and adapt to new challenges and opportunities. The next time you see a diesel fuel dispenser at a fuel station, take a moment to appreciate the intricate machinery and the important role it plays in our daily lives. It's not just a machine; it's a key player in the grand symphony of transportation and industry, a silent yet powerful force that keeps the world moving.