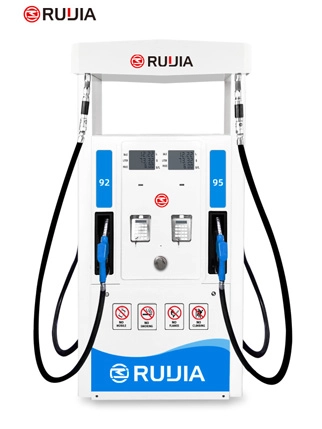

Fuel Dispenser With Hose Reel

Product Parameter

- Product Name

- RJ66 Fuel Dispenser

- Brand Name

- Ruijia

- Product Size

- 400X380X550mm

- Flow Rate

- 5~80L/min

- Flow Meter

- 4- piston Flow Meter

- Pump

- Vane Pump

- Lcd Display

- 886 or 664

- Temperature

- -25°C~ +55°C

- Pressure

- 0.3MPa

- Accuracy

- ±0.3%

- Voltage

- AC220V,DC12V,DC24V

- Suction Distance

- 6m(vertical), 20m(horizontal)

- Power

- 550W

- Medium

- Gasoline, Diesel, Kerosene

Product Configuration

Our Certification

What is a Fuel Dispenser With Hose Reel?

Ever pull up to a fuel station and find yourself marveling at the coiled, snake - like hose neatly tucked away on a rotating contraption attached to the fuel dispenser? That's not just an ordinary addition – it's a game - changing feature that transforms a standard fuel dispenser into a more efficient, user - friendly, and organized machine. But what exactly is this fuel dispenser with a hose reel, and how does it redefine the refueling experience? Is it merely a convenience feature, or does it bring a host of other benefits that are often overlooked? Prepare to have your eyes opened as we delve into the fascinating world of these specialized fuel dispensers!

At first sight, the fuel dispenser with a hose reel might look like its regular counterparts at a glance. But take a closer look, and you'll notice the distinct, cylindrical reel mounted on the side or top of the dispenser, housing the fuel hose. It's like a hidden treasure chest, holding the key to a smoother, more streamlined refueling process. This seemingly simple addition isn't a random afterthought; it's the result of careful engineering and a deep understanding of the challenges and pain points associated with traditional fuel hoses.

The hose reel, at its core, is a mechanical or motorized device designed to wind and unwind the fuel hose with ease. Think of it as a well - trained butler, always ready to present the hose when needed and neatly stow it away when the job is done. This functionality might sound straightforward, but it has far - reaching implications for both the user experience and the overall operation of the fuel dispenser. Gone are the days of struggling with long, cumbersome hoses that drag on the ground, get tangled, or pose tripping hazards. With a hose reel, the hose is always within easy reach, neatly organized, and protected from the elements.

Let's start exploring the inner workings of this ingenious addition. Mechanical hose reels often rely on a spring - loaded mechanism. As you pull the hose out to refuel your vehicle, the spring inside the reel winds up, storing energy. Once you're done refueling and release the hose, the spring unwinds, gently pulling the hose back into place. It's a bit like a retractable tape measure – you extend it when you need it, and it automatically retracts when you're finished. Motorized hose reels, on the other hand, take this convenience to the next level. Powered by electric motors, these reels can be controlled with the push of a button or integrated into the dispenser's control system. They offer smoother operation, greater precision, and can handle heavier - duty hoses with ease. It's like having a personal assistant that not only retrieves the hose for you but also neatly puts it away, without you having to lift a finger.

The benefits of a fuel dispenser with a hose reel extend far beyond just convenience. For starters, it significantly reduces wear and tear on the hose. In traditional setups, hoses are often left lying on the ground, exposed to sunlight, oil spills, foot traffic, and other elements. This constant exposure can lead to cracks, leaks, and premature deterioration. With a hose reel, the hose is elevated off the ground and protected when not in use. It's like giving the hose a cozy, protective home, shielding it from the harsh realities of the outside world. This not only extends the lifespan of the hose but also reduces maintenance costs for fuel station operators. Fewer hose replacements mean fewer expenses and less downtime for the dispenser.

Safety is another area where the hose reel shines. Tripping hazards caused by loose, dragging hoses are a common concern at fuel stations. A simple misstep while walking around a fuel dispenser could lead to a dangerous fall, especially in areas where there might be fuel spills or slippery surfaces. The hose reel eliminates this risk by keeping the hose off the ground and neatly coiled. Additionally, it helps prevent accidental kinking or pinching of the hose, which could disrupt the fuel flow or even cause a rupture. It's like having a safety net in place, ensuring that both customers and employees can move around the fuel dispenser without worrying about potential accidents.

For customers, the hose reel enhances the overall refueling experience. No more struggling to untangle a knotted hose or having to awkwardly maneuver a long, heavy hose around your vehicle. With a hose reel, the hose glides out smoothly, allowing you to reach your vehicle's fuel tank with ease. And when you're done, the automatic retraction feature means you don't have to worry about neatly coiling the hose yourself. It's a small but significant improvement that can make a big difference in how customers perceive the fuel station. A hassle - free refueling experience can lead to increased customer satisfaction and loyalty.

But the advantages don't stop there. Fuel dispensers with hose reels also offer better space management at fuel stations. Instead of hoses lying haphazardly around the dispenser, taking up valuable space and creating a cluttered appearance, the hose reel keeps everything tidy and organized. This not only makes the fuel station look more professional but also allows for more efficient use of the available space. In busy fuel stations with multiple dispensers, this can be a game - changer, enabling more vehicles to be fueled simultaneously without the hoses getting in each other's way. It's like a well - choreographed dance, where every element has its place and moves in harmony.

When it comes to different types of fuel dispensers, hose reels can be integrated in various ways. Some are designed as standalone attachments that can be retrofitted onto existing fuel dispensers, providing an easy upgrade option for fuel station owners. These aftermarket hose reels often come with detailed installation instructions and can be installed by trained technicians with relative ease. Other fuel dispensers are manufactured with the hose reel already built - in, as an integral part of the design. These integrated models offer a more seamless look and can be optimized for better performance, as the dispenser and hose reel are engineered to work together from the ground up.

The materials used in the construction of hose reels are also carefully selected. Durability is key, as these reels need to withstand the rigors of daily use, exposure to different weather conditions, and the weight of the fuel hose. Many hose reels are made from high - strength metals such as stainless steel or aluminum, which offer excellent corrosion resistance and structural integrity. Some also feature rugged, weather - resistant coatings to further protect against the elements. The internal components, such as the springs or motors in mechanical and motorized reels respectively, are also built to last, with regular maintenance ensuring their smooth operation over time.

In the world of industrial and commercial fueling, fuel dispensers with hose reels are especially valuable. In large fleet yards, where multiple vehicles need to be refueled quickly and efficiently, the hose reel's ability to keep hoses organized and easily accessible can significantly improve the refueling process. Construction sites, too, benefit from these dispensers. With heavy machinery and equipment constantly on the move, having a fuel dispenser with a hose reel means that refueling can be done safely and without disrupting the workflow. It's like having a reliable team member that's always ready to support the operations, ensuring that the machines never run out of fuel due to inconvenient or inefficient refueling setups.

Looking ahead, the future of fuel dispensers with hose reels is filled with exciting possibilities. As technology continues to advance, we can expect to see even more innovative features integrated into these devices. For example, smart hose reels that can monitor the condition of the hose, detect leaks or wear, and send alerts to maintenance staff. Or hose reels that are fully automated and can be controlled remotely, perhaps through a central management system at the fuel station. Additionally, with the increasing focus on sustainability, there may be a push to develop hose reels made from more eco - friendly materials or that are designed to be more energy - efficient in the case of motorized models.

In conclusion, the fuel dispenser with a hose reel is not just a simple accessory; it's a revolutionary addition that has transformed the way we think about refueling. From its practical benefits in terms of convenience, safety, and hose longevity to its impact on the overall customer experience and fuel station operations, this seemingly small feature packs a big punch. As we move forward, it will undoubtedly continue to evolve and adapt, playing an even more crucial role in the fueling industry. So, the next time you pull up to a fuel dispenser with a hose reel, take a moment to appreciate the engineering marvel that it is – a testament to human ingenuity and the constant pursuit of making our lives easier, one refueling at a time.