- 20+ Years Of History

- 30+ Countries

- 50000 Yearly Production

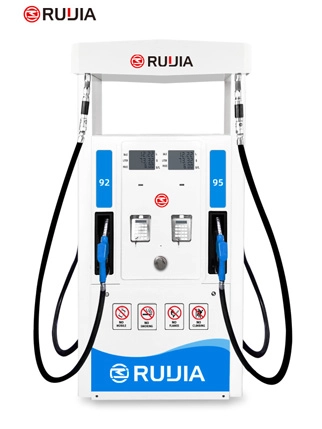

What Are Fuel Dispensers?

Fuel dispensers, commonly referred to as gas pumps, are essential components of modern fueling stations, playing a critical role in the global transportation and energy sectors. These devices are designed to deliver fuel from underground storage tanks to vehicles efficiently, safely, and accurately. While their primary function is to refuel cars, trucks, and other vehicles, fuel dispensers are also integral to the broader energy supply chain, supporting the distribution of gasoline, diesel, and alternative fuels. Over the years, advancements in technology have transformed fuel dispensers into sophisticated systems that integrate electronic components, smart features, and environmental safeguards. This article explores the definition, internal structure, safety mechanisms, types, technological innovations, and the broader significance of fuel dispensers in the modern world.

The Evolution and Importance of Fuel Dispensers

The concept of fuel dispensers dates back to the early 20th century, when the rise of the automobile industry necessitated a reliable method for distributing fuel. The first fuel dispensers were simple mechanical devices, often requiring manual operation and lacking precise measurement capabilities. However, as vehicle usage increased and fuel efficiency became a priority, the design of fuel dispensers evolved to meet the demands of both consumers and industry standards.

Today, fuel dispensers are far more advanced, incorporating digital technology, automated systems, and safety features that ensure accurate fuel delivery and minimize risks. They are not only found at traditional gas stations but also at specialized locations such as truck stops, airports, and industrial facilities. Their importance extends beyond individual convenience; fuel dispensers are vital to the smooth operation of commercial transportation, emergency services, and logistics networks. Without these devices, the movement of goods and people would be significantly hindered, highlighting their critical role in the global economy.

Understanding the Function and Components of Fuel Dispensers

At their core, fuel dispensers are complex systems that combine mechanical and electronic components to deliver fuel to vehicles. The basic structure of a fuel dispenser includes several key parts, each contributing to its overall functionality:

1. Pump System

The pump is the heart of a fuel dispenser, responsible for drawing fuel from underground storage tanks and pushing it through the system. Modern pumps are typically electrically powered and designed to handle various types of fuels, including gasoline, diesel, and alternative fuels like compressed natural gas (CNG) or hydrogen. The pump must operate efficiently under varying conditions, ensuring a steady flow of fuel while maintaining pressure levels to prevent disruptions.

2. Flow Meter

The flow meter is a critical component that measures the volume of fuel being dispensed. Traditional flow meters used mechanical systems, such as rotating gears, to track fuel volume, but modern dispensers often rely on electronic sensors for greater accuracy. These meters are calibrated to ensure precise measurements, which are essential for fair billing and preventing overfilling. Some advanced flow meters also include features like temperature compensation to account for variations in fuel density.

3. Control Panel

The control panel serves as the user interface for fuel dispensers, allowing drivers to select the type of fuel they want and initiate the dispensing process. It typically includes a digital display that shows the price per gallon, the total amount of fuel dispensed, and the cost. Many modern dispensers also feature touchscreens or keypads for easier navigation. The control panel is connected to the pump and flow meter, ensuring seamless communication between components.

4. Nozzle and Hose

The nozzle is the part of the fuel dispenser that connects to the vehicle's fuel tank. It is designed to regulate the flow of fuel and prevent spills. The nozzle includes a safety mechanism that automatically stops the flow when the tank is full, reducing the risk of overfilling. The hose, which connects the nozzle to the pump, is made of durable materials to withstand exposure to fuel and environmental conditions. It is also equipped with a swivel joint to allow flexibility during refueling.

5. Pressure Regulators

Pressure regulators are essential for maintaining a consistent flow rate of fuel. These devices ensure that the fuel is delivered smoothly without excessive pressure, which could damage the vehicle's fuel system or cause leaks. Pressure regulators also help prevent fluctuations in fuel flow, ensuring a stable and efficient refueling process.

6. Anti-Overfill System

One of the most important safety features of a fuel dispenser is the anti-overfill system. This mechanism detects when a vehicle's fuel tank is full and automatically stops the flow of fuel. It works by using a sensor in the nozzle that senses the rising fuel level. When the tank is full, the sensor triggers a valve to close, preventing spills and reducing the risk of fire or environmental contamination.

Safety Features of Fuel Dispensers

Given the flammable nature of fuel, safety is a top priority in the design and operation of fuel dispensers. Several key safety features are integrated into modern dispensers to protect users, the environment, and the surrounding infrastructure.

1. Anti-Overfill System

As mentioned earlier, the anti-overfill system is crucial for preventing fuel spills. When a vehicle's tank is full, the sensor in the nozzle detects the rising fuel level and stops the flow. This not only protects the vehicle from overfilling but also reduces the risk of fuel escaping into the environment, where it could cause pollution or ignite.

2. Static Electricity Dissipation

Static electricity can accumulate during the fueling process, posing a risk of sparks that could ignite fuel vapors. To mitigate this, fuel dispensers are equipped with grounding systems that safely discharge static electricity. A grounding wire connects the dispenser to the vehicle, ensuring that any static charge is neutralized before it can cause a hazard. This feature is particularly important in dry or low-humidity environments, where static buildup is more likely.

3. Fireproof Design

Fuel dispensers are constructed using flame-resistant materials to minimize the risk of fire. The electrical components are also designed to prevent sparks, and many dispensers include emergency shut-off systems that can be activated in case of a malfunction or accident. These systems immediately stop the flow of fuel, reducing the likelihood of fire or explosion.

4. Pressure Relief Valves

Pressure relief valves are another critical safety feature that prevents excessive pressure buildup within the fuel dispenser. These valves release excess pressure in the system, ensuring that the dispenser remains functional and safe. By maintaining a stable pressure level, these valves help prevent ruptures or explosions that could occur if the system were to overpressurize.

Types of Fuel Dispensers

Fuel dispensers are designed to accommodate a wide range of fuels and vehicle types. The following are the most common types of fuel dispensers:

1. Gasoline Fuel Dispensers

Gasoline dispensers are the most widely used type of fuel dispenser, found at traditional gas stations. They are designed to handle regular, premium, and mid-grade gasoline, each with different octane ratings. These dispensers are equipped with high-precision flow meters and are often integrated with electronic payment systems for convenience. Gasoline dispensers are also designed to handle the volatility of gasoline, ensuring that fuel is delivered safely and efficiently.

2. Diesel Fuel Dispensers

Diesel dispensers are specifically designed for vehicles that run on diesel fuel. They are built to withstand higher pressures and are equipped with more robust components to handle the thicker consistency of diesel. Some diesel dispensers include features like diesel particulate filters to reduce emissions and improve fuel efficiency. These dispensers are commonly found at truck stops and commercial fueling stations, where diesel-powered vehicles are prevalent.

3. Electric Vehicle (EV) Charging Stations

With the rise of electric vehicles, EV charging stations have become an essential part of the fueling infrastructure. Unlike traditional fuel dispensers, these stations provide electricity to charge vehicle batteries. They come in various forms, including Level 1, Level 2, and DC fast chargers, each offering different charging speeds and power outputs. EV charging stations are often equipped with smart technology that allows users to monitor their charging progress and manage payments through mobile applications.

4. Compressed Natural Gas (CNG) Dispensers

CNG dispensers are used to refuel vehicles powered by compressed natural gas, a cleaner-burning alternative to gasoline and diesel. These dispensers are designed to handle the high-pressure nature of CNG and include specialized valves and pressure regulators to ensure safe and efficient fueling. CNG dispensers are commonly found in areas where CNG vehicles are popular, such as public transportation systems and fleet operations.

5. Alternative Fuel Dispensers

In addition to gasoline, diesel, and CNG, fuel dispensers are also available for other alternative fuels, such as liquefied petroleum gas (LPG), hydrogen, and ethanol. These dispensers are tailored to meet the specific requirements of their respective fuels, ensuring safe and efficient refueling. For example, hydrogen dispensers require specialized storage and delivery systems to handle the unique properties of hydrogen fuel.

The Impact of Modern Technology on Fuel Dispensers

Modern technology has revolutionized the functionality and efficiency of fuel dispensers, making them more advanced, user-friendly, and environmentally friendly. The integration of electronic systems, smart features, and data-driven solutions has transformed the way fuel is dispensed and managed.

1. Electronic Systems and Digital Integration

Traditional fuel dispensers relied on mechanical components for measurement and control. However, modern dispensers incorporate electronic systems that enhance accuracy and reliability. Digital flow meters, microprocessors, and sensors provide precise fuel measurements, reducing the risk of errors. Additionally, electronic systems enable real-time monitoring of fuel levels, allowing operators to track inventory and optimize refueling operations.

2. Smart Fuel Dispensers

Smart fuel dispensers are equipped with Internet of Things (IoT) technology, enabling remote monitoring and maintenance. These dispensers can communicate with central systems, providing data on fuel consumption, equipment performance, and potential malfunctions. This level of connectivity allows for proactive maintenance, reducing downtime and improving operational efficiency. Smart dispensers also support contactless payment methods, such as mobile wallets and RFID cards, enhancing the convenience of the refueling experience.

3. Environmental Impact Reduction

As environmental concerns grow, fuel dispensers are being designed to minimize their ecological footprint. Low-emission dispensers and eco-friendly technologies are being developed to reduce fuel evaporation and harmful emissions. Some dispensers include features like vapor recovery systems, which capture fuel vapors during refueling and prevent them from entering the atmosphere. Additionally, advancements in fuel efficiency monitoring allow users to track their vehicle's fuel consumption, encouraging more sustainable driving habits.

4. Integration with Renewable Energy Sources

The shift toward renewable energy has also influenced the design of fuel dispensers. Some stations now offer hybrid dispensers that can accommodate both traditional fuels and renewable energy sources, such as solar or wind power. These dispensers are part of broader efforts to create a more sustainable energy infrastructure, reducing reliance on fossil fuels and promoting cleaner alternatives.

Maintenance and Troubleshooting of Fuel Dispensers

Regular maintenance is essential to ensure the optimal performance and longevity of fuel dispensers. Neglecting maintenance can lead to malfunctions, safety hazards, and inaccurate fuel measurements. The following are key aspects of fuel dispenser maintenance:

1. Routine Inspections

Operators should conduct daily inspections of fuel dispensers to check for signs of wear, leaks, or damage. This includes examining the pump system, flow meter, nozzle, and hose for any issues that could affect performance. Electrical components, such as wiring and sensors, should also be inspected to ensure they are functioning correctly.

2. Cleaning and Lubrication

Fuel dispensers should be cleaned regularly to prevent the buildup of dirt, debris, or fuel residues that could clog the system. Lubricating moving parts, such as the pump and valves, helps maintain smooth operation and extends the lifespan of the dispenser. Operators should follow manufacturer guidelines for cleaning and lubrication schedules.

3. Calibration of Flow Meters

Accurate fuel measurement is crucial for fair billing and customer trust. Flow meters should be calibrated periodically to ensure they provide precise readings. Calibration involves comparing the dispenser's measurements to a known standard and adjusting the system as needed. This process helps prevent discrepancies and ensures compliance with regulatory standards.

4. Troubleshooting Common Issues

Despite regular maintenance, fuel dispensers may encounter issues that require troubleshooting. Common problems include low fuel pressure, inaccurate measurements, and malfunctioning payment systems. For example, if a dispenser fails to dispense fuel, the operator should check the pump motor and electrical connections. If the flow meter is inaccurate, recalibration or replacement may be necessary. Promptly addressing these issues helps maintain the reliability and performance of the dispenser.

The Role of Fuel Dispensers in the Energy Sector

Fuel dispensers are not just tools for refueling vehicles; they are integral to the energy sector, supporting the distribution of fuels that power transportation, industry, and everyday life. Their role extends beyond individual convenience, influencing economic growth, environmental sustainability, and technological innovation.

1. Supporting Transportation and Logistics

The transportation sector relies heavily on fuel dispensers to keep vehicles running. From personal cars to commercial trucks and delivery vehicles, fuel dispensers ensure that the movement of goods and people remains uninterrupted. In industries such as freight, agriculture, and construction, fuel dispensers are essential for maintaining operational efficiency and meeting deadlines.

2. Economic Impact

Fuel dispensers contribute to the economy by creating jobs in the fueling and retail sectors. They also generate revenue for gas stations, convenience stores, and other businesses that depend on fuel sales. Additionally, the development and maintenance of fuel dispensers drive innovation in engineering, manufacturing, and technology, fostering economic growth and job creation.

3. Environmental and Regulatory Compliance

As environmental regulations become stricter, fuel dispensers are being designed to meet higher standards for emissions and safety. Features like vapor recovery systems and low-emission fueling help reduce the environmental impact of fueling operations. Compliance with these regulations not only protects the environment but also ensures that fuel dispensers remain operational in regions with strict environmental laws.

4. Future Trends and Innovations

Looking ahead, fuel dispensers are expected to continue evolving to meet the demands of a changing energy landscape. The increasing adoption of electric vehicles will drive the development of more advanced EV charging stations, while the push for renewable energy will lead to the integration of solar and wind-powered dispensers. Additionally, the use of artificial intelligence and machine learning in fuel dispensers could enhance predictive maintenance, optimize fuel distribution, and improve the overall user experience.

Conclusion

Fuel dispensers are more than just gas pumps; they are sophisticated systems that play a vital role in the global energy infrastructure. From their mechanical components to their advanced technological features, fuel dispensers ensure the safe, efficient, and accurate delivery of fuel to vehicles. As technology continues to advance, these devices will become even more integrated with smart systems, environmental safeguards, and renewable energy solutions. Whether refueling a personal car, a commercial truck, or an electric vehicle, fuel dispensers remain indispensable in the modern world. Their continued evolution will shape the future of transportation and energy, ensuring that fueling remains a reliable and sustainable process for generations to come.